preliminary pompom

Testing the velvet-suitability of a mystery silk.

As I reach my first goal of having enough bobbins to weave a small test of velvet, it’s time to look up from the lathe and consider the other elements still needed to weave velvet, starting with the silk. Not all silk yarn is well-suited to velvet weaving, so how can I make the correct choice?

what makes a good velvet silk?

Velvet is a tufted warp-pile material. This means the silk warp threads are woven in tight loops, which are then split open with a sharp razor-like blade. The cutting of the fibres at such a tightly-packed density and short length creates a tufted effect, where the silk ends spray out and into each other, resulting in the uniform, strokable texture of velvet we all know.

In order to tuft effectively, the silk yarn should have a high number of filaments and be spun with either no or very little twist. Too high a twist creates a “corded” effect and the cut yarns won’t tuft out into each other evenly. Too few filaments will result in too thin a velvet. Additionally, the silk should be soft, with a high sheen. Velvet is a plush, luscious material that requires softness of fibre. The high sheen that results in softened silk also allows velvet to catch the light at different angles as it is stroked.

choosing a test silk

The purpose of these first velvet mini-samples is to test the bobbins and my own understanding of velvet construction, before I charge ahead with the carving of 1000 bobbins. It should give me time to understand the density and yarn counts I will want to be working with, and to test the range of base warp material I can weave with. I also want to have as little commitment as possible to purchasing silk for this test. I have been in touch with a silk yarn supplier for when I will need larger quantities, and these tests should help me identify the best yarn count to order.

Looking through my existing collection of silk, I had a few silks that could be suitable for velvet, but only one where I felt I might have enough quantity to weave enough samples. It is a silk yarn brought back from Japan by my friend Mika, and it has been sitting on my yarn shelf for some years, as I have waited to find the perfect use for such a beautiful yarn.

From translating the label that came with the silk, I believe it is a low-twist yarn made of 36 filaments at 21 momme (“momme” is the Japanese yarn count for silk). It has been wrapped around a frame circumference of 1,27m a total of 800 times, which should give the yarn a total length of 1.016m. The fineness of the filaments and their high count, along with the generous length and low-twist should qualify this silk as a good choice for velvet.

The only downside to the Japanese silk is its stiff texture. It has a firmness to it which feels similar to coarse hair. My past work with chirimen made me wonder if this stiffness is the finished texture of the silk, or caused by a protein coating, similar to the sericin used to lock in the high twist in chirimen.

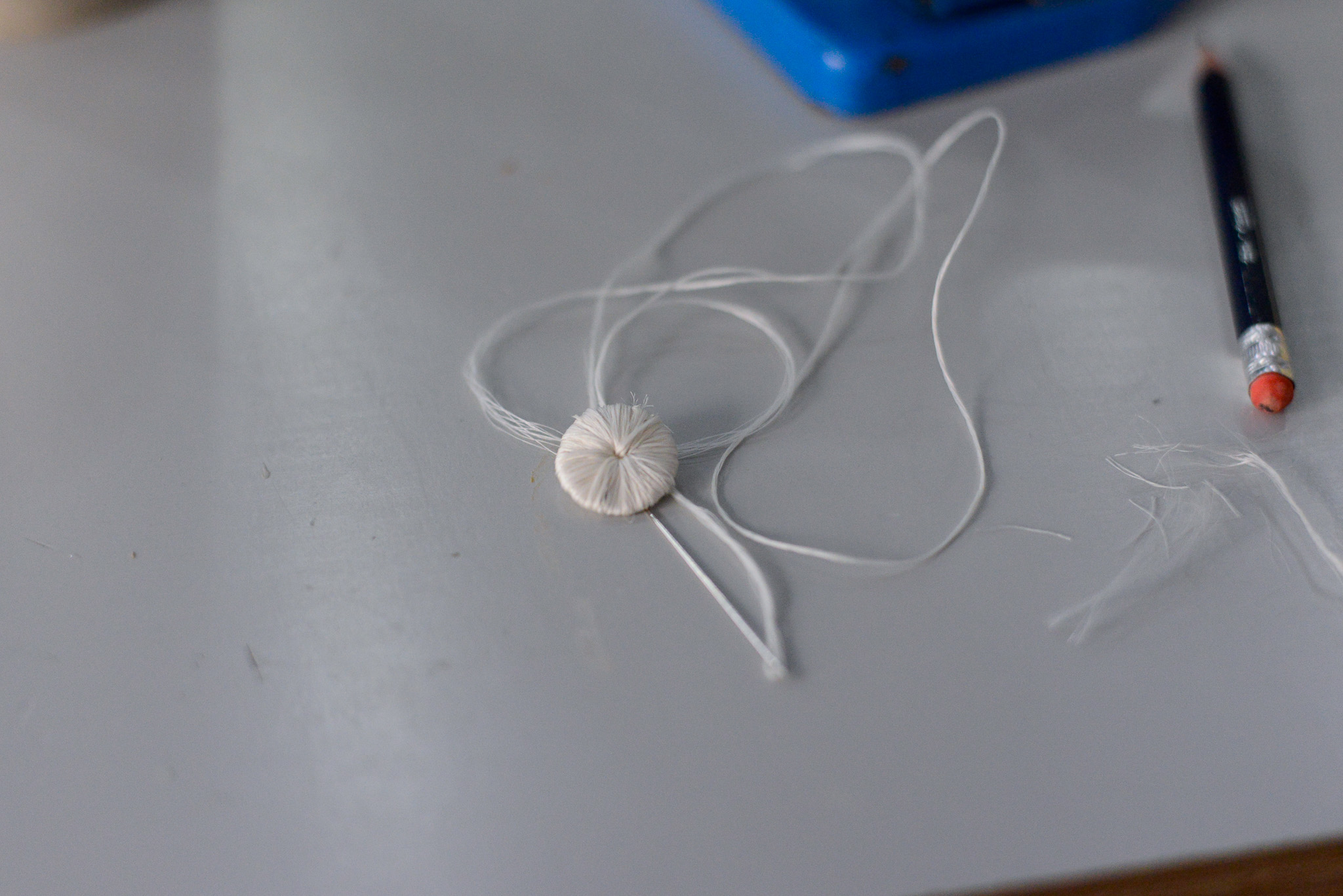

making the pompom

I needed a velvet-suitability test that would meet the following requirements:

- use minimal material

- relatively quick to produce

- no loom required

- holds silk yarn firmly at a high density

- allows for silk yarn to be cut/tufted)

- can be boiled for multiple hours without losing form (to remove any protein coating)

A pompom seemed the perfect answer. The size can be adjusted as needed, the yarn packs together tightly and is tufted, and its form is solid enough to withstand boiling without falling apart. And as a bonus, I find it an incredibly satisfying textile process, consistenly looping thread, building up equal layers, splitting open the filament ends.

I didn’t have any Natron to hand in the studio, so I boiled the pompom in a solution of water and Waschsoda. I also eyeballed the ratio, using my experience from the chirimen weaving. I didn’t need to fully finish the pompom to a professional silk standard, I only wanted to get a rough enough result to see if there was indeed some form of stiffening coating on the silk.

The pompom finished almost exactly as I’d hoped. The tufted filaments spread out and into each other, creating a uniformly textured surface. It also softened significantly and developed a shinier, glossier finish, indicating the yarn does indeed have some form of removable protein coating. It didn’t soften quite as much as I would hope for from the finished result, but I attribute this to not using the correct chemical agent (Waschsoda instead of Natron) and not boiling the pompom for long enough.

So there it is! With over 1000m of this silk yarn left to play with, this should be an ideal material for the first velvet tests. Next task: making the rods.

Datenschutzerklärung — Impressum

©Emma Wood 2025